Navigation Sensors

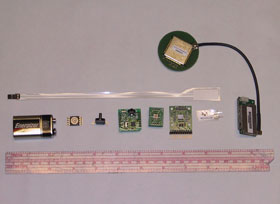

To determine the trajectory of a three-dimensional body in space, it is necessary to measure three orthogonal axes of acceleration/velocity/position and three axes of angular velocity/orientation. The new MEMS sensors used in devices such as Nintendo's Wii controllers and Apple's iPhone(trademark battle still in progress) provide accelerometers and rate-gyroscopes at remakably low cost. The present plan is to use one of Analog Devices' ADXL78 family for the high-g acceleration along the rocket axis, and an ADXL320 to measure the moderate acceleration in two directions orthogonal to the rocket axis. Two of InvenSense's IDG300s will be used to measure angular velocity in three mutually orthogonal axes. The axial direction will have redundant angular sensing.

In addition, most modern inertial measurement units (IMU) include GPS and possibly magnetic fields. We are evaluating the Garmin GPS 15 (which has a 1 SPS update rate), and the Atmel ATR0635 (which has a 4 SPS update rate) for use as our GPS sensor, and PNI Corp.'s MicroMag3 for three-axis sensing of the earth's magnetic field.

Model and hobby rockets have long flown pressure sensors to determine altitude. Our chosen pressure sensor is the Freescale MPXAZ4115A, another MEMS device. It is an absolute pressure sensor that will be used for altitude determination. Freescale makes a differential pressure sensor, the MPXV7025G, that we plan on evaluating for suitability in a Pitot-tube-style velocity sensor. It should be able to measure velocities up to 450 MPH.

If we are successful with our data-collection design, we should have enough processing power to combine the outputs from these 13 sensors in a Kalman filter to calculate the acceleration, velocity, location, angular velocity, and orientation of the rocket in real time with a fair degree of accuracy.

We have also begun work on the board-sensor integration. We have purchased various sensor solutions for measurements of pressure, temperature, and vibration. We’ve instrumented one model rocket body with piezoelectric vibration sensors and measured the response of the body when subjected to a tap test. We launched an initial vibration sensor flight test in November 2006. We had telemetry lock on both the on-board video and the on-board sensors (acceleration, pressure-altitude, and vibration) for the entire flight. The results have been posted on the project website (www.eng.hmc.edu/NewE80). We are currently working on the next test launch scheduled for April 2006 in which we will test six vibration sensors simultaneously as well as a carbon-fiber/Kevlar composite body tube. Additional test flights are planned as the design progresses. For the initial test flights, we are using the RDAS system and custom sensor boards.