Nanocomposite Gas Separation Membranes

Project Background: To efficiently and effectively separate gas mixtures, membranes must exhibit both high gas permeability (fast transport) and high selectivity for one gas over the other. Unfortunately, these properties tend to be diametrically opposed: membranes made of rubbery polymers have high permeabilities but low selectivities, while membranes made of glassy polymers have high selectivities but low permeabilities. It has long been accepted that the addition of micron-sized inert impermeable particles to a polymer film decreases the permeability while leaving the selectivity unchanged. However, recent research has shown that adding nanoparticles to a special class of glassy polymers results in an increase in permeability, while retaining or possibly even improving the selectivity.

Project Background: To efficiently and effectively separate gas mixtures, membranes must exhibit both high gas permeability (fast transport) and high selectivity for one gas over the other. Unfortunately, these properties tend to be diametrically opposed: membranes made of rubbery polymers have high permeabilities but low selectivities, while membranes made of glassy polymers have high selectivities but low permeabilities. It has long been accepted that the addition of micron-sized inert impermeable particles to a polymer film decreases the permeability while leaving the selectivity unchanged. However, recent research has shown that adding nanoparticles to a special class of glassy polymers results in an increase in permeability, while retaining or possibly even improving the selectivity.

Our Work: We are examining the crossover between permeability enhancement and reduction with changes in particle size and polymer type. Understanding these effects will allow for the design of tunable membranes for gas separations.

- Experimental: We study gas permeation in a wide range of polymer types and nanoparticle sizes, and have developed a one-pot technique for creating well-dispersed nanocomposite membranes.

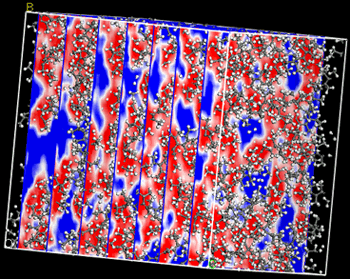

- Modeling: We develop molecular models (Materials Studio, Accelrys) to examine the molecular-level interaction between the polymer and nanoparticles.

- Characterization: We use Scanning Electron Microscopy (SEM) to obtain images of our composite films. We also send samples to other labs for free volume determination via positron annihilation lifetime spectroscopy (PALS) and Transmission Electron Microscopy (TEM) imaging.

Click here to see a brief video about this work. To read more about the students involved in this project, click here. Interested in joining this research team? Please click here for more information.